Product attributes (specifications)

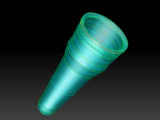

| Product name | Thin-wall tube molding | Usage | Thin-wall tube molding |

|---|---|---|---|

| Material | PP | Size | φ5 x 12 |

| Product design | Customer provided drawings | Mold design | Designed at Shinwakogyo |

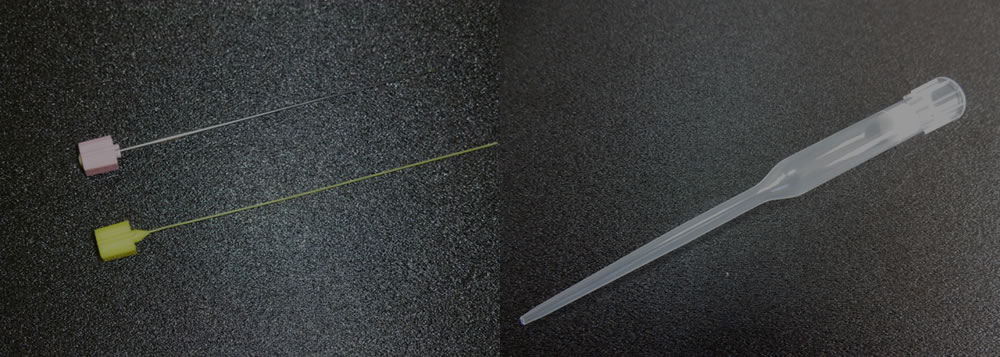

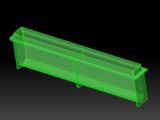

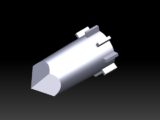

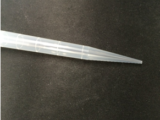

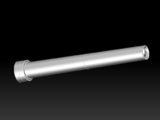

Product images (status)

|

|

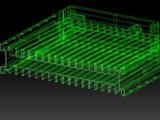

Overview

Among medical plastic products, there is a need for real-time PCR tubes to minimize the wall thickness of the body. Real-time PCR tubes need to conduct heat well because of repeated heating and cooling. However, when the wall thickness is reduced, even if the misalignment between the mold core and the mold is very few, it results a large uneven thickness product. For example, if the product thickness of the tube is as thin as 0.4 mm, if the misalignment between the mold and the core is 0.05 mm, the thick side is 0.45 mm and the thin side is 0.35 mm, which the difference is 0.1 mm. A misalignment of 0.05 mm is a 25% displacement of 0.4 mm. Therefore, at the time of mold design, it is necessary to devise a mechanism for aligning the mold with the core. When optimizing plastic molding conditions, it is also important to take care to avoid uneven thickness.