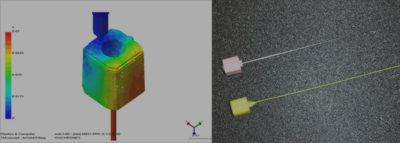

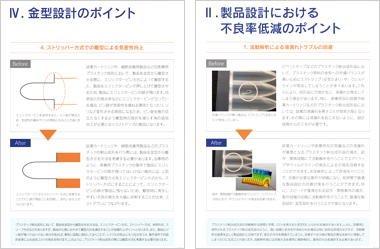

It is said that product development costs are determined 70% or more at the design stage. In addition, most of shape accuracy and quality stability are determined not at the molding stage but at the design stage. For these reasons, Shinwakogyo puts importance on VA / VE proposals from the design stage to development designers more than contract processing of molding.

Shinwakogyo has the abundant experience of realizing VA / VE together with development designers, such as improving the functions of customers’ products and improving the price competitiveness of the market, while maintaining the functions fulfilled by the parts that make up the product. Please feel free to contact us if you are interested in any of the issues listed below or are interested in developing them.

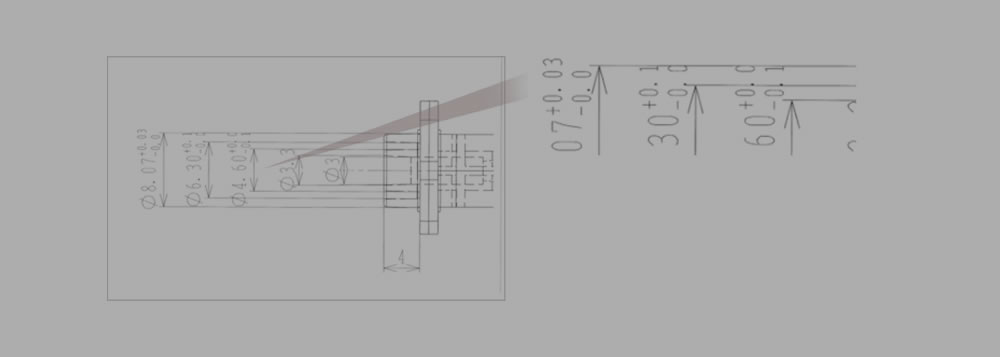

- Reduction of total cost of parts from mold design / production to mass production

- Reduction of the failure rate by proposals of changing the part shape and the mold design stage

- We perform total coordination, such as selecting the best materials and, if necessary, suggesting sterilization methods.

This “MedicalPlasticMolding.com” is a site that summarizes some examples of these VA / VE proposals as “Points of VA / VE for medical plastics”. We provide technical information specialized in the medical industry and molding in a before-after style. If any of the cases are not listed, please send us your drawings and issues and we will respond to individual technical consultations.

| < VA / VE proposal > | < before – after style example > |

|

|