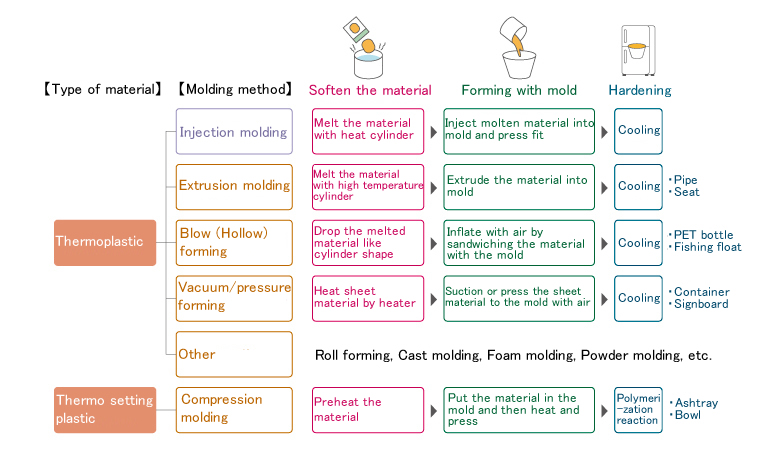

In addition, plastics are roughly classified into two types.

(1)Thermoplastic

Plastics that become softer when heated and are easier to process, and harden when cooled are called thermoplastics. It is common that materials called with “Poly-” such as polyethylene and polycarbonate are classified into this thermoplastic.

(2)Thermosetting plastic

When heated, it becomes a little softer, but if you continue to heat the plastic, a molecular bridge will be formed between the chains of molecules, and it will change to a network-like hard property. This is called thermosetting plastic. Plastics called with “-resin” such as phenolic resin and urea resin are classified as thermosetting plastics.

Type of plastic molding