Product attributes (specifications)

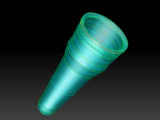

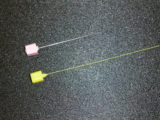

| Product name | Medicine vessel part | Usage | Medicine vessel part spout |

|---|---|---|---|

| Material | PE | Size | φ40~50 x 50~60 |

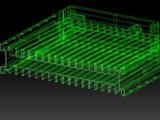

| Product design | Customer provided drawings | Mold design | Designed at Shinwakogyo |

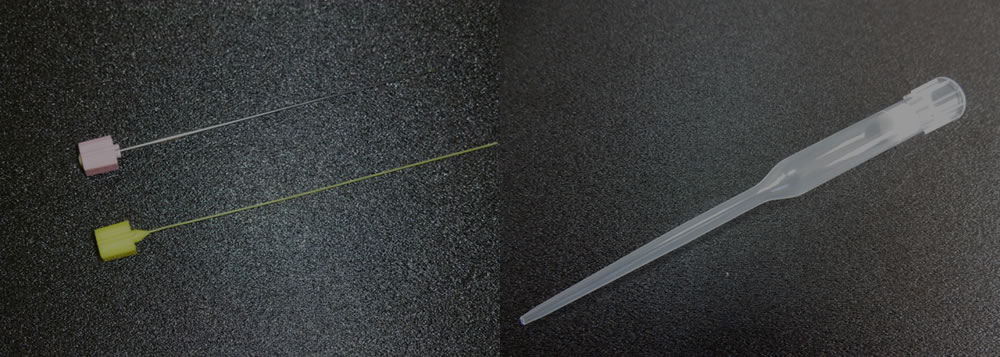

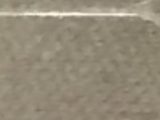

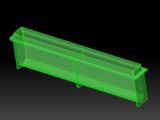

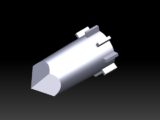

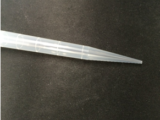

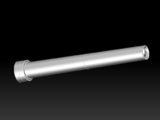

Product images (status)

|

|

Overview

Liquid leakage is a fatal defect in spouts for chemical containers. It is also necessary to pay attention to the roundness of the opening, which is the seal part with the inner ring of the cap, the scratch inside the opening and the scratch or burr on the top side of the opening if the contact ring of the cap is a seal.

In the case of plastic chemical containers, there is a tendency to attach importance to especially chemical resistance among polyethylene. Therefore, the melt flow rate of the specified material is often low, and it is necessary to fill with a high resin pressure, which tends to distort the product. Furthermore, when designing the mold, it is necessary to give due consideration to everything from the runner to the gate.

When molding plastic in a clean room, after taking out the product with the take-out robot, care must also be taken with the robot hand so that the opening is not scratched.