Product attributes (specifications)

| Product name | Anesthesia needle core | Usage | Anesthesia needle core for medical use |

|---|---|---|---|

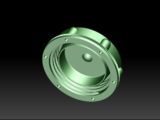

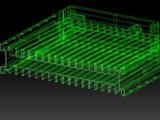

| Material | PP | Size | φ8.0 x 125 |

| Product design | Customer provided drawings | Mold design | Designed at Shinwakogyo |

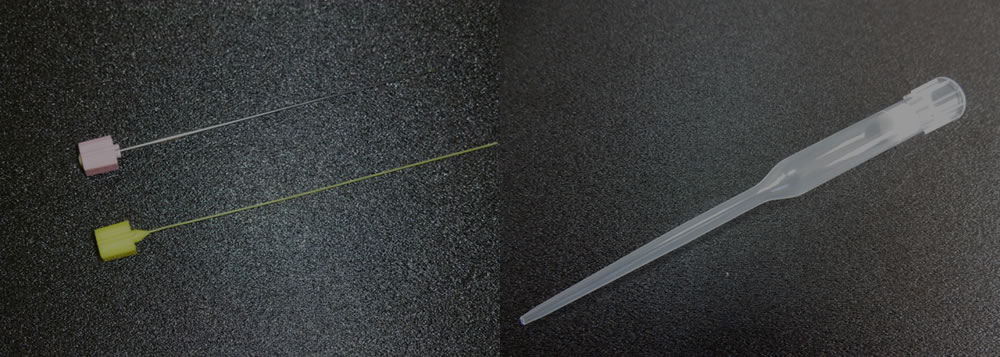

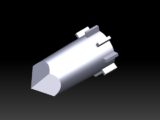

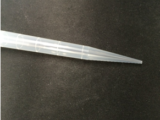

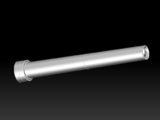

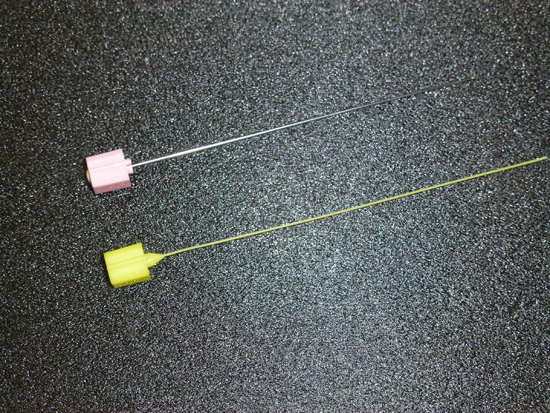

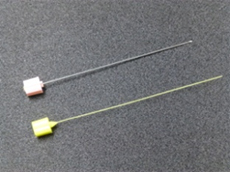

Product images (status)

|

|

Overview

In general, the anesthesia needle core that adheres a cap to a thin metal pin is the mainstream in the industry, but the core of this anesthesia needle core is an integrally molded product. We have realized the production of products that meet the required specifications that the taper of the narrow part of φ0.6 and 125 mm is 0 degree and particle lines (PL), split lines and voids are strictly prohibited. There are many types of needle core lengths, and the tip is cut according to the length of the needle, so it cannot be used if there is a void in the cut surface.

In addition, the advantages of the one-piece molded product are (1) safe (when handling with a metal anesthesia needle core, there is a risk of infection by accidentally stabbing a nurse's hand, but with plastic it is safe due to soft), possible to be used for patients with metal allergies (when a metal core rubs against the inside of the needle, a small amount of metal powder was generated, but using a plastic does not generate metal powder even if rubbed), (3) easy disposal (all materials are plastic and can be processed together), (4) possible to be cost reduction (material cost is lower than metal and there is no bonding process) and other.