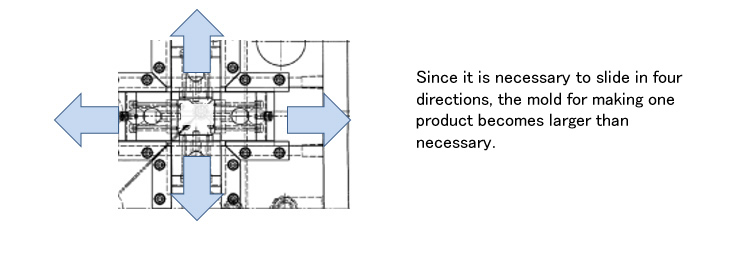

Before (改善前)

For a plastic product for medical use, if undercutting and mold slides in four directions as described above for the undercut processing are required, the area occupied by one mold will be large. As a result, the number of products obtained in one mold decreases, production efficiency deteriorates, and production costs increase. In addition, the size of the mold is larger than that of plastic injection molded products, and the cost of the mold is also increased, which significantly increases the production cost.

V

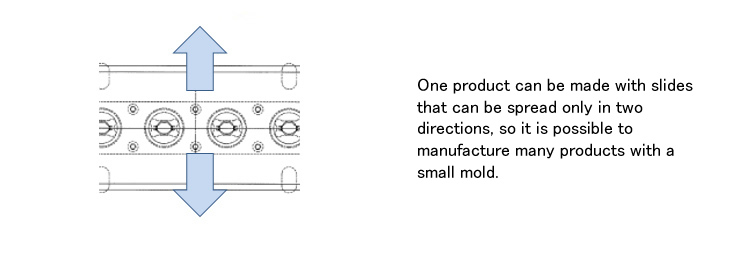

After (改善後)

When manufacturing plastic molded parts, there is a close relationship between the number of products and the product unit price in mold production, and when determining the number of products, it is need to be considered whether the total production cost can be reduced. In order to increase the number of products obtained from a mold and increase production efficiency, it is important to simplify the mold structure at the product design stage and minimize the area occupied by one cavity. For example, as described above, by changing the design to a structure that can be manufactured by sliding from four directions to two directions, the number of products obtained is greatly increased, the size of the mold is significantly reduced, and the total cost can be reduced.

POINT(要約)

When making parts for medical plastic products that are expected to be mass-produced with like by injection molding, production efficiency can be improved by considering the number of products that can be manufactured by one cycle of machine operation. It is an important point in cost reduction. In particular, if the size of the injection molding machine is too large for small parts, the control of injection is extremely difficult, it is needed to consider at the product design and mold design that products match the part size, mold size, and injection molding machine size.