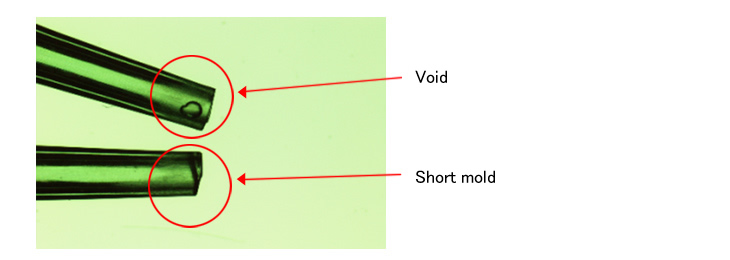

Before (改善前)

In the case of plastic injection molded products for medical use with an extremely thin part, because the plastic resin does not easily flow into the thin part, the filled plastic raw material does not flow to the flow end and the pressure does not reach enough, a short mold or void may occur. Short molds are fatal defects for plastic products, and if such products leaked to the market, serious complaints such as leakage of contents or functional defects may be a concern.

V

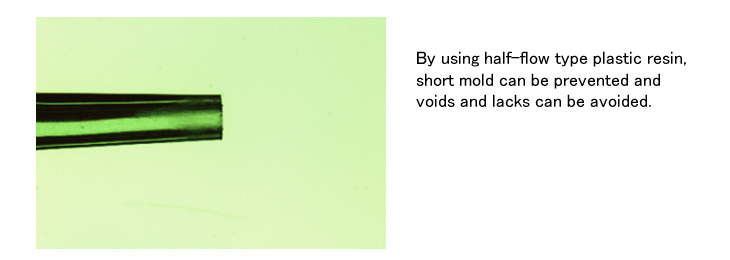

After (改善後)

In the case of thin plastic injection molded products, by using a low-viscosity and high-flow type plastic resin which allows the plastic resin to be filled neatly even in thin places, short molding may be avoided. When manufacturing high-quality thin molded products, it is necessary to consider the characteristics of the plastic resin used from the design stage. However, even with the use of high-flow type plastic resin, note that to fill extremely thin portions is difficult.

POINT(要約)

Typical examples of thin-walled medical plastic injection molded products include tips and tubes that handle samples and reagents. Some of these plastic products require frequent heating and cooling during use, and thinner molded parts tend to be preferred for better heat transfer. However, among the thin plastic injection molded products, the minimum thickness is generally said to be 0.4 mm. Injection molding is not impossible even with 0.4 mm or less, but 0.4 mm is generally the minimum thickness because advanced mold design technology, processing technology and molding technology corresponding to them are required.