Before (改善前)

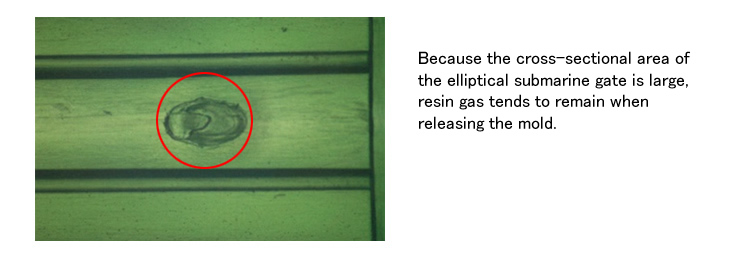

One type of gate in plastic injection molding is a submarine gate. Submarine gates are available in two types, elliptical or D-shaped, depending on how the gate is processed into the mold. Generally, there are many mold manufacturers that manufacture molds with an elliptical cross section. However, if an elliptical mold is used for the submarine gate, the mold processing is easy, but the gate may not be easily cut because resin residue may be generated depending on the plastic due to the large cross-sectional area during releasing. As a result, the quality of the finished surface of the injection molded product may be poor.

V

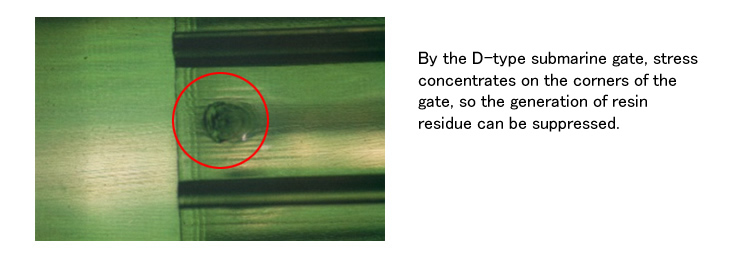

After (改善後)

When a submarine gate is used in plastic molding for medical use, the D-shaped gate shape cuts the finished surface of the plastic injection molded product neatly, which leads to improved quality of the molded product. Since the shape of the submarine gate is type, stress concentrates on the corners of the gate, so that the resin is more likely to be cut during release and the quality of the release surface is improved. In addition, since the cross-sectional area can be reduced with the D-type gate, resin orientation is less likely to occur, so that the generation of resin residue can be suppressed.

POINT(要約)

When using a submarine gate, the gate cross section will be elliptical or D-shaped depending on the processing method of the mold manufacturer. In general, many mold manufacturers use an easy-to-process method, so the cross section is elliptical. On the other hand, to process a cross-section into a D-shape, though the processing method differs depending on the material and shape of the mold part at the gate part of the mold, it require more processing steps compare to the processing of the elliptical cross-section shape. The D-type gate improves cutting quality because stress during cutting is concentrated on the corners.