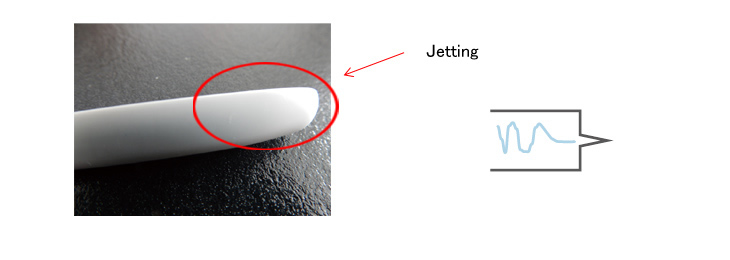

Before (改善前)

In the case of thick parts or deep plastic injection molded products, the distance from the gate to the mold is long, so the plastic resin is filled like a bobbin. As a result, a phenomenon called jetting, in which the flow marks that meander on the surface of the molded product remain and fixed with cooling down. Jetting also makes the appearance worse, and depending on the intended use, the product must be discarded, which may increase costs.

V

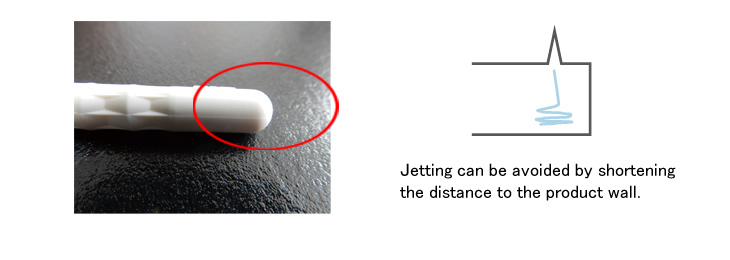

After (改善後)

Jetting can be avoided by changing the position of the gate of plastic injection molded products and shortening the distance from the gate to the product wall of the mold. In addition, by reducing the gate diameter in accordance with that, the filling speed of the plastic resin is increased, so that the filling can be done more smoothly. As a result, jetting can be suppressed, and it is possible to avoid discarding or recreating plastic injection molded products due to defective products.

POINT(要約)

In plastic injection molded products, although it is said that jetting is likely to occur particularly in thick parts (the distance from the gate to the product wall is long), moreover voids (holes) and sink marks tend to occur. In addition to changing the position of the mold gate, the occurrence of sink marks and voids can be suppressed by increasing the mold temperature or plastic resin temperature. When manufacturing thick plastic injection molded medical devices, it is necessary to consider the product shape and molding conditions. It is necessary to write notes on the product drawings such as sink marks are prohibited strictly to call attention when designing the mold.