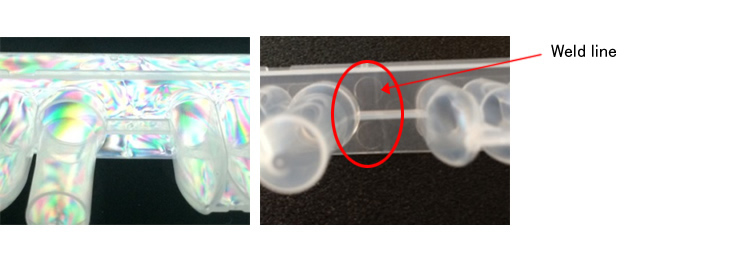

Before (改善前)

In the medical field such as medical test kits, if the gates are multi-point gates when molding plastics for medical use, welds will occur where the resin flow is joined in the mold. The part where the weld has occurred is where the resin is merged, so the strength is reduced. In addition, using a multipoint gate makes it easier for gas to accumulate at the point where the resin joins, and in some cases an air trap may be generated. In such cases, excessive compression of the air may cause resin burning or poor filling, causing short molding.

V

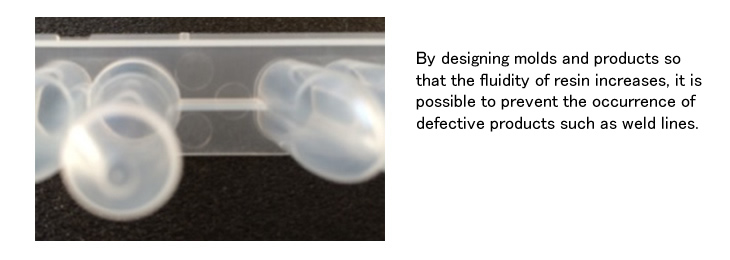

After (改善後)

When molding medical plastics, it is desirable to be able to fully fill the resin with as few gates as possible to prevent poor quality such as welds. For that purpose, it is necessary to improve the fluidity of the plastic when injected. As a countermeasure, change the thickness of the product at the design stage, use ribs to reinforce the strength, and use a flow leader so that the plastic can flow from one gate to the end of the product, this leads to improved product quality.

POINT(要約)

In the molding of medical plastics, reducing the number of gates as much as possible, increasing the fluidity of the resin to be injected for fully filling are the points for improving the quality of products. In the past, there were few plastics with good fluidity, so it was the theory that plastic injection molding was carried out with a multi-point gate using thick runners, but the injection power has been increased drastically with driven by electrical power. In addition, due to technological advances in material development, high flowable plastic grades have also been created, so it is now common to use a small number of gates with a thinner runner.