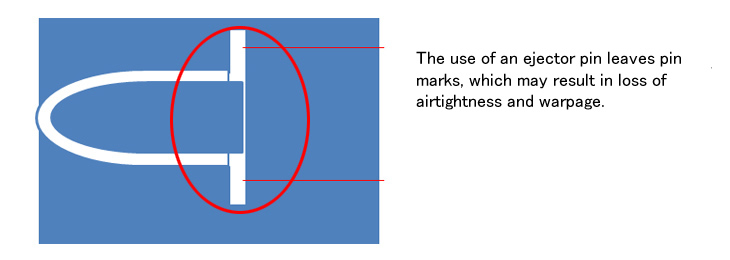

Before (改善前)

In medical plastic molding such as reagent cartridges and cell culture products, when the product is released from the mold by the ejector pin method, pin marks remain because the product is pushed up by the ejector pin and released. If the ejector pins are standing at the joints with other parts, additional processing as reducing the friction at ejection is required to reduce the pin marks, which increases the cost because the pin marks may impair airtightness or cause deformation such as warping.

V

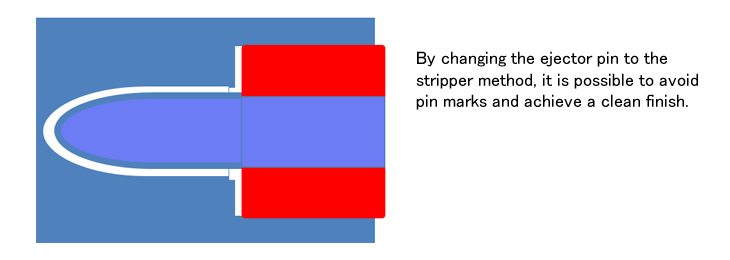

After (改善後)

When performing injection molding of plastics such as reagent cartridges and cell culture products, it is necessary to consider the method of releasing the product from the mold. As in this case, if the trace of the ejector pin should not remain on the product during the production of medical plastic, by changing from the ejector pin method to the stripper method as shown in the above figure, because no trace is left on the product, it can significantly reduce the occurrence of defects that tend to occur during mold release, leading to cost reductions.

POINT(要約)

In plastic injection molding, products can be released from the mold by an ejector pin method, stripper method, combined method, sleeve method, etc. The quality improvement point is to select a release method according to product specifications. In addition, if there is any part of the product not allows pin marks, noting it in the drawing in advance will not only prevent problems, but also prevent additional costs due to design changes during manufacture. Thus, it is necessary to consider the release method when plastic injection molding.