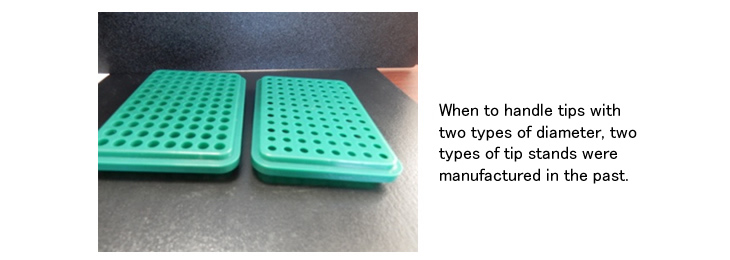

Before (改善前)

In medical plastic molding, if there are multiple design objects and they have similar shapes, using only one side of the product can only be used for a product. In this case, in the above picture, even if you try to make tips of multiple diameters, only one diameter can be used in the exact size. Therefore, when handling tips with multiple diameters, it is necessary to manufacture molds according to the size of the tips, which increases initial costs and increases costs.

V

After (改善後)

When manufacturing medical plastic parts, if possible, change the diameter of the hole between the front and back, and make the inside of the product a tapered structure so that two types of diameter of tip can be inserted on both sides with only using one mold. By adopting a reversible structure in this way, plastic injection molded products that can be used in two different diameters can be obtained from one type of mold, leading to a reduction in initial costs and cost reductions.

POINT(要約)

When manufacturing plastic injection molded products, the cost of the mold is the biggest factor in cost increase. Therefore, it can be said that one of the effective methods to reduce costs in plastic injection molding is to make the specifications of the mold more efficient. In this case as well, manufacturing a reversible part that can be used with multiple diameters from one mold can significantly reduce costs.