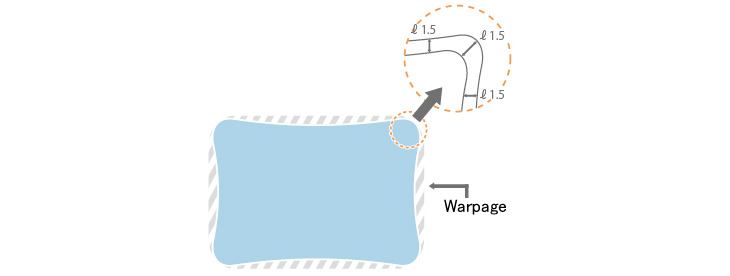

Before (改善前)

When manufacturing plastic injection molded products of square containers such as racks for storing tips, it takes a long time to cool because only the corners have more heat than other parts. Therefore, warping may occur starting from the corner of a rectangular container. If warpage occurs, the fitting with the lid will not fit in the case of a container such as a tip case, so a lot of man-hours will be required for the assembly work, and the lead time of the product will be lengthened by that work.

V

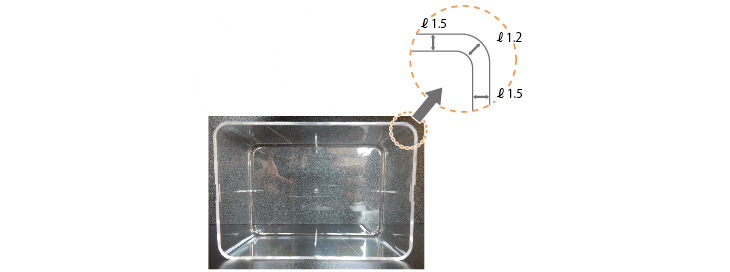

After (改善後)

In the case of a square-shaped plastic injection-molded product, by changing the design of the corner to a thinner wall, cooling efficiency can be increased and warpage can be prevented. There are methods to reduce the thickness of the corners and side surfaces with an R shape, or to make the corners C-cut. In plastic injection molding, although the mold design technology and molding technology have a large effect on the cost of the finished product. It is possible to manufacture stable high quality plastic injection molding products with small ingenuity at the product design stage like this case.

POINT(要約)

When changing the corners of plastic injection molded square containers, such as tip cases used for medical applications, to thinner corners, note that if the corners are too thin, insufficient strength may occur and filling balance will be worse. Insufficient strength and filling balance depend on the strength and fluidity of the plastic resin used, so it is necessary to determine the conditions for plastic injection molding in consideration of the characteristics of the plastic resin used when designing products.