Before (改善前)

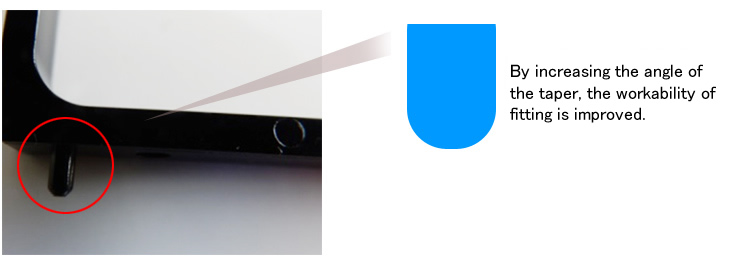

Some plastic injection molded products for medical use are made of a combination of multiple parts, and these parts may be assembled by fitting each other. If there is no gap between the mating parts that acts as a “Nozoki” (invitation) to some extent, the work efficiency of the assembly work will deteriorate. For products used for medical purposes, cleaning and autoclave are frequently performed because they need to be kept clean. However, if there is no gap between the fittings, it will take time and effort to disassemble.

V

After (改善後)

If it is designed as the fitting force can be adjusted at the design stage of plastic injection molding, the efficiency of assembly work will increase, and costs will be reduced by reducing man-hours. For example, a taper is used, and the beginning of the fitting is used as a “Nozoki” with “loose fitting” so that the fitting can be firmly fitted as the parts are inserted deeper. Also, products that are frequently cleaned and autoclaved, such as plastic injection molded products for medical equipment, can be easily removed.

POINT(要約)

The fitting method includes boss fitting, undercut fitting, and slide fitting. The designer must instruct the drawing where the mating adjustment is required in advance. This is because the mold designer can adjust the mating force by performing additional machining of the mold when designing the mold. If there is no such instruction and the dimensions of the mold parts do not allow adjustment of the fitting, if a problem occurs, the part will have to be re-manufactured anew, it will be a great disadvantage for reducing costs and delivery time.