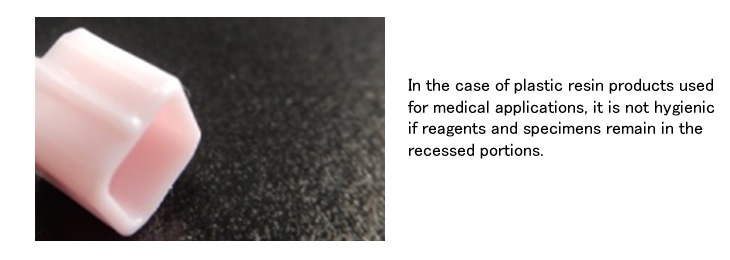

Before (改善前)

There are various reagents and specimens at the site where medical equipment is used, and these reagents and specimens may come into contact with medical equipment. If there are projections and recesses on the surface of the medical device, there is a risk that reagents and samples will remain on the surface of the medical device. In recent years, there have been many medical devices that emphasize nice cosmetics, but if there are unnecessary projections and recesses, reagents and specimens will remain there, causing unsanitary and contaminant causes, leading to deterioration in quality.

V

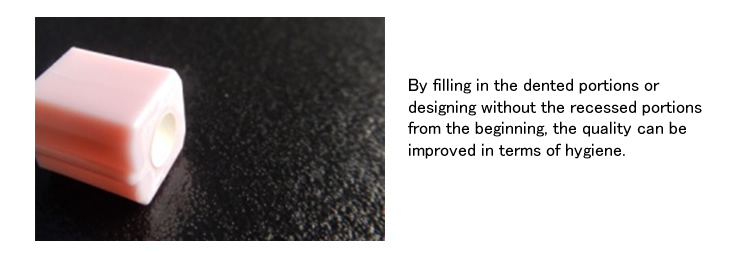

After (改善後)

In medical plastic molding, if a specimen or reagent enters a recessed part, that part becomes unsanitary. Therefore, product design is also important, but by eliminating the recesses in the product as much as possible, reagents and samples can be prevented from entering, it can be possible to achieve to improve hygiene and prevent contamination, and improve quality. In the case of molded plastics for medical use, it is necessary to design especially considering the usage environment and intended use.

POINT(要約)

In designing medical device products, cosmetic is also an element. However, compared to other products, medical devices where sanitary conditions such as sterilization are very important to produce products that have a high level of satisfaction in terms of quality, such as preventing burr and welds. In order to design products that achieve high levels of satisfaction in quality, it is important to have the view of doctors and nurses who actually work in the field.