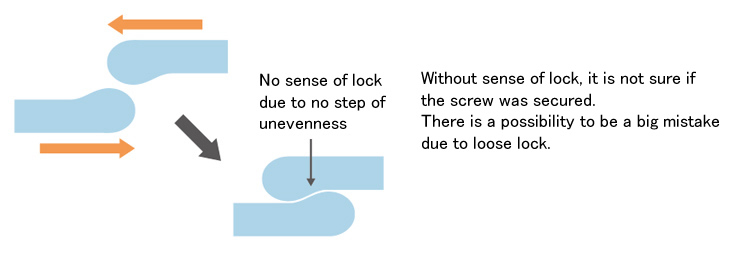

Before (改善前)

When using plastic products used in medical sites, often it is used that the hands’ feeling of actual users, such as doctors, nurses, and researchers at various laboratories. In general, plastic products used in the medical field, unless a mechanism that gives a sense of lock during work is not provided, can not rely on the sense of the hand, which can lead to work errors. As a result, if the products are used without secure state, it may result to be serious mistakes like that the plastic product may come off or fall off.

V

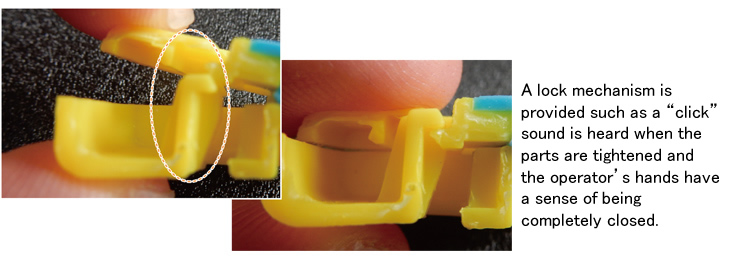

After (改善後)

Products used in the medical field are often used a combination of multiple plastic molded parts, and it is common to provide a lock mechanism as a “foolproof mechanism” to prevent operation errors. In order to create a lock or click feeling with the lock mechanism, it is necessary to create a hard part and a soft part and combine them. By a “click” sound is heard when the parts are tightened as described above, it is possible to prevent the mistakes because the operator can confirm that the parts are securely tightened.

POINT(要約)

When manufacturing plastic molded products used in the medical industry, it is important to implement a foolproof mechanism in order to eliminate operational errors when used by doctors, nurses, and researchers at various testing laboratories. In particular, plastic injection molded products for medical use often handle reagents, and small mistakes can lead to large mistakes. Therefore, by designing products to occur no work errors from the beginning, it is possible to prevent major mistakes.