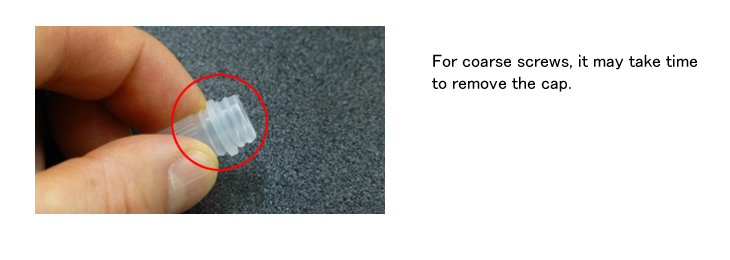

Before (改善前)

When designing medical plastic products such as microtubes and centrifuge tubes, the design may be simply made with ordinary coarse screws for a screw structure. However, on medical sites, there is a case that it may not be necessary for the thread to have a locking mechanism because pressure may be applied to the thread. In such a case, considering that it is used conveniently during surgery or treatment, turning the screw and removing the cap etc. would be troublesome, which would lead to lower user satisfaction.

V

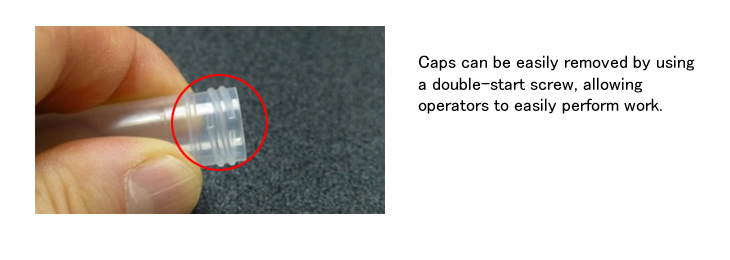

After (改善後)

When designing medical plastic products with threaded parts such as microtubes and centrifuge tubes, it is important to design products in consideration of where they will be used. When it is required to be able to use one hand for surgery or treatment at the medical site, by using a screw with a thread lead larger than the pitch, such as a double-start screw, the rotation work is half that of a normal screw and it can be easily tightened. The ability to easily tighten the screw with one hand will increase user satisfaction.

POINT(要約)

When manufacturing medical plastic products, it is important to design the product from the design stage, taking into account the use and environment of the actual product. When deciding the number of threads of screw, whether it is two, three, or more, or adopt a fine pitch, it is necessary to know what is actually required in the field based on the actual user’s voice. It is important to increase the number of threads if the screw should be removed immediately, and to use a fine pitch screw if the screw should be hard to remove.