Before (改善前)

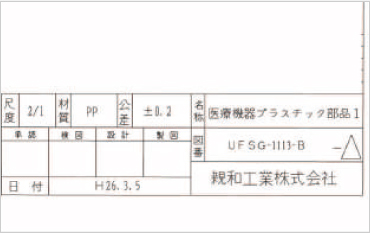

When manufacturing plastic injection molded products for medical use, there are cases that required to use medical grade plastic resin. Unlike general-purpose plastic resins, the grades recommended for medical applications are limited in type and may be difficult to obtain. Also, since only the type of plastic resin is specified, the grade is not known, so it is necessary to arrange several types of grades and make prototypes, which may lead to a longer lead time until completion .

V

After (改善後)

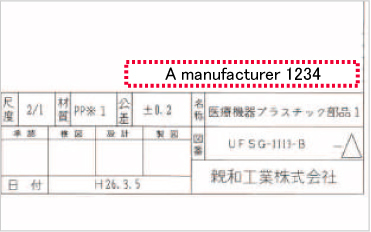

In the case of plastic injection molded products, it is necessary to specify not only the type of plastic resin but also the grade. If medical grade plastic resin is required, it is necessary to consider in advance the intended use and the characteristics of the plastic resin (such as shrinkage and filling properties). And the cooperation of resin manufacturers is indispensable. The customer, the resin manufacturer, and the plastic injection molding manufacturer can tie up to make prototype and develop, so that the most suitable plastic resin can be selected and the plastic injection molded product can be manufactured.

POINT(要約)

Depending on the size of the plastic injection product, for example, if you use a plastic resin with a shrinkage of 0.001% larger than 100 mm length of polypropylene, a difference of 0.1 mm will occur by itself. If the tolerance on the drawing of this product is ± 0.1 mm, extra work will be required to discriminate the products out of tolerance. Especially in mass production, it is very difficult to keep all products within tolerance. As described above, it is necessary to consider the characteristics of the plastic resin used in product design.