Before (改善前)

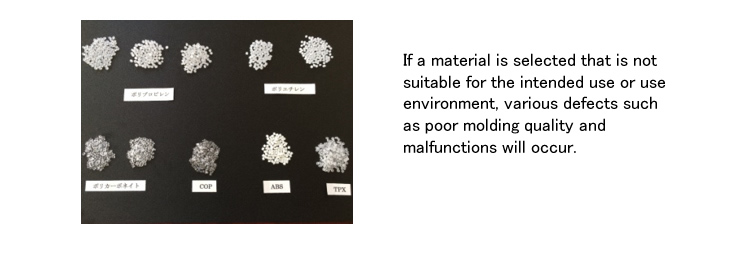

In the case of manufacturing plastic molded products for medical use, because both polypropylene and polyethylene have the property of chemical resistance, if these plastic resins are easily selected, a problem may occur depending on the use environment and intended use. In addition, if the shape of the plastic injection molded product is complex, thin, or very narrow, the raw material will not be filled properly depending on the type and grade of the plastic resin, so short shots, burrs and other quality defects may occur.

V

After (改善後)

When manufacturing plastic molded products for medical use, it is important to select the appropriate resin for the intended use of the product to improve quality. Even though both polypropylene and polyethylene have chemical resistance, it is important to select a resin according to the use environment and product requirements. In addition, by selecting the optimal plastic resin according to the shape of the plastic injection molded product, filling will be stable and it is possible to avoid quality defects such as short shots and burrs.

POINT(要約)

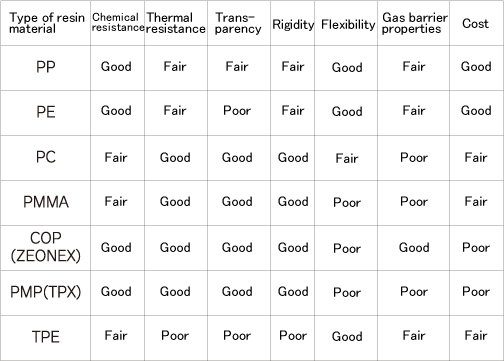

When performing plastic injection molding for medical and biotechnology, it is necessary to select resin materials according to product shapes and required specifications. Plastics and resins have various characteristics depending on their types, such as transparency, thermal resistance, chemical resistance, rigidity, flexibility, hinge properties, and gas barrier properties. Therefore, the point of quality improvement is to select the appropriate resin by considering thoroughly the characteristics of each plastic resin and the shape, intended use, and use environment of the plastic injection molded product.