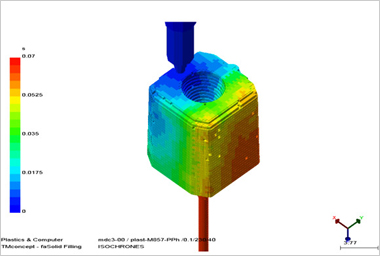

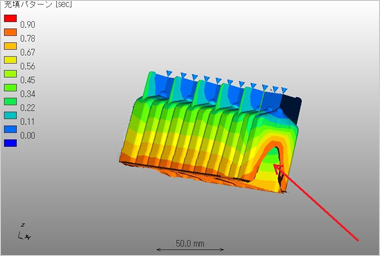

Not only for medical plastics (resins), there are two factors that greatly affect the accuracy of their products: molding conditions and molds. The first molding condition is affected by the temperature and pressure at which the plastic (resin) is injected.

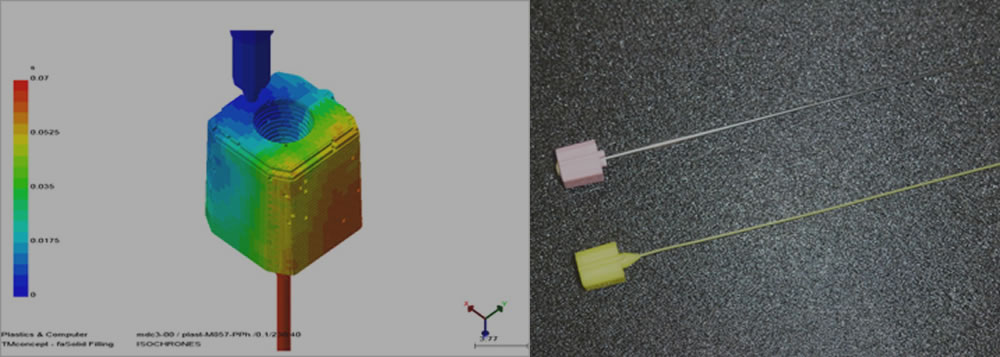

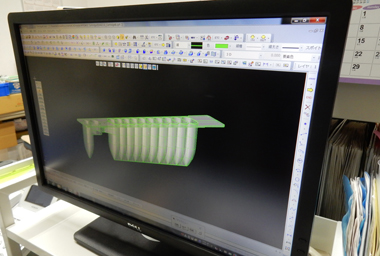

And the shape and precision of the two molds depend on this condition. Our company, “MedicalPlasticMolding.com”, introduced 3DCAD as a specialized molder ahead of the industry. This has enabled sophisticated and versatile molding simulations at the mold design stage, which is difficult for other companies in the same industry, and has realized the development efficiency and quality of plastic products.

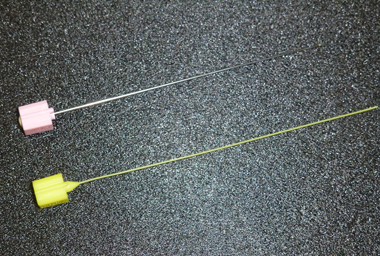

As a past record, by the flow based on this 3D data and unique molding know-how, we realized design and manufacturing of molds that enables mass-production with ultra-high-speed filling, medical plastic product shape of φ 0.6, length 135 mm, no draft angle and no burrs which are not be achieved by other companies.

“Medical Plastic Molding.com” is asked consultation of product development with customers due to the mold technology that realizes this difficult-shaped plastic molding. There are also consultations on the remodeling of the molds that have already been manufactured, and we can respond to the remodeling depending on the customer’s mold conditions.

*Modification of existing molds may not be possible depending on the condition of the mold and the contents after modification.

| < Simulation / flow-analysis > | < Fine plastic molding > |

|

|

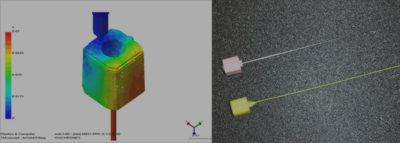

| < Simulation / flow-analysis > | < 3D modeling > |

|

|