In the field of medical treatment, fertility treatment has mainly been research and treatment for women, but recently research and treatment for men has been advanced. Until now, there has been no container with excellent functionality and convenience for storing sperm. After consultation with a teacher who thought about the solution, the development of a specialized container for transporting and storing sperm, Transporter S, started.

This page introduces the development flow of the sperm storage / transport container: Transporter S.

Whole process of improvement / design / development for conventional products

We introduce the case that the contents of joint development of medical plastic products through consulting with Shinwakogyo Co., Ltd., which operates "Medical Plastic Molding.com".

1.Problem of current product

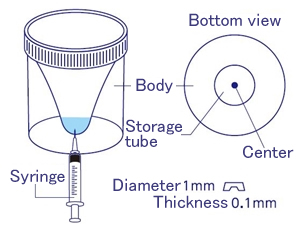

Conventional sperm storage and transport container |

The current sperm storage and transport container used to be general plastic containers. |

2.Consultation from customers

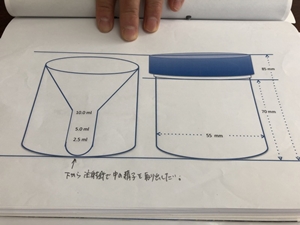

Draft of sperm storage and transport container |

We had a consultation based on an idea from a customer who was thinking to develop a container for storing and transporting sperm that solves the problem of the current product. |

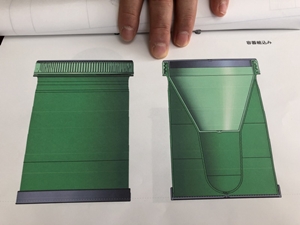

3.Proposal from us using CAD

Proposal to upgrade the functionality based on the draft |

By using 3D-CAD to design the needs of customers and doctors (professors) to use, we prepare models with 3D printers, and then the customer confirmed the actual sample model by having by customer’s hand. |

4.Design and production of mold and prototype

Provision of prototypes |

Once the product design is completed, the next step is to design the mold and then make the mold. |

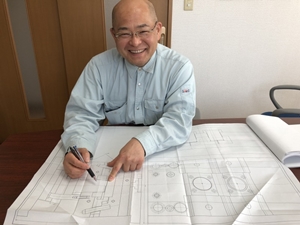

5.Final meeting for the product

Detailed meeting based on the final drawing |

After the mold was manufactured, actual molding was conducted. After the customer confirmed the mass-produced products, we had meetings for final product specifications, packaging specifications, gamma-ray sterilization specifications, and gamma-ray irradiation tests to complete as a medical plastic product. |

6.Completion of new product development

Completed sperm storage / transport container |

The development of a new product specialized in unprecedented sperm storage and transport containers completed after many discussions and crating prototypes for the new product with the customer and doctors (professors). |

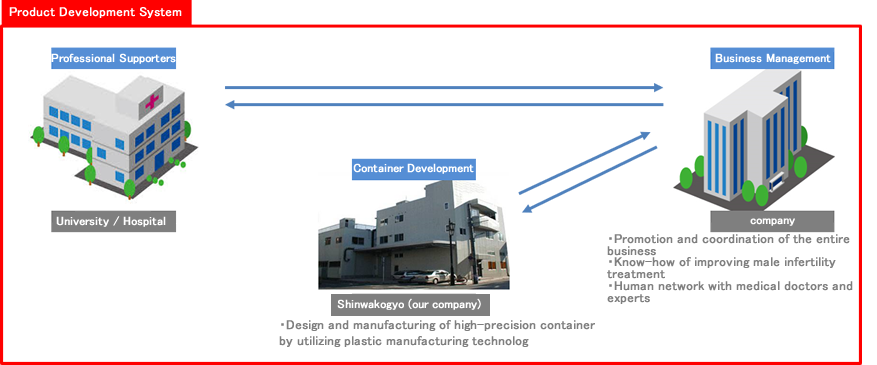

①Professional Supporter: University / Hospital ②Business Management: Company

③Container Development: Business promotion system by Shinwakogyo (Our company)

This case was that the joint development by a company that strongly wished to improve the conventional

sperm transport / storage container, a university / hospital which supports the company, and

Shinwakogyo which provided plastic molding technology.

To realize a new sperm transport method that contributes to improving the treatment results of infertility:

・Reduction of deterioration risk

・Improvement of user convenience and relief of anxiety

・Improvement of treatment results

Introduction of "Transporter S", or the High-performance sperm transport / storage container

Here we introduce the whole picture of the Transporter, or high-performance sperm transport and storage container and transporter, which commercialized after consultation.

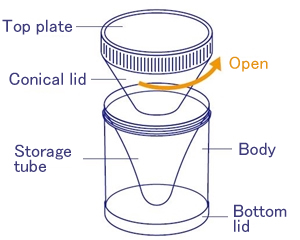

1.Remove the conical lid from the body

|

<Notes> |

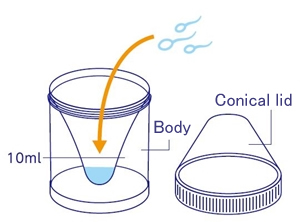

2.Get sperm on the body

|

|

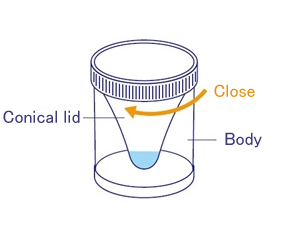

3.Store / transport

|

|

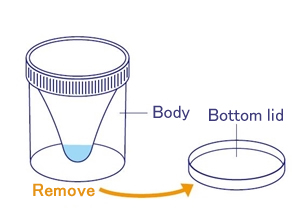

4.Preparation of retrieval

|

|

5.Retrieval of ejaculated sperm

|

|

6.Use

|

|

※ Excerpt from the user’s manual of Transporter S

Rich experience in designing and manufacturing medical plastic molded products

Shinwakogyo operates the specialized medical site, "Medical Plastic Modling.com" and receives orders for the design and manufacture of medical plastic products through the site. (Please check HP for details)

-

- Rich experience in designing and manufacturing medical plastic molded products

Ability to propose shape and technology related to molding that to enable to achieve customer's product concept and plan

In many cases, the final shape of the product is not fixed. In such a case, Shinwakogyo will make a proposal after understanding the functional aspects of the product during the meeting. At the time, we will improve the functional and cost aspects by shortening the product manufacturing process based on our specialized molding technology.

-

- Ability to propose shape and technology related to molding that to enable to achieve customer's product concept and plan

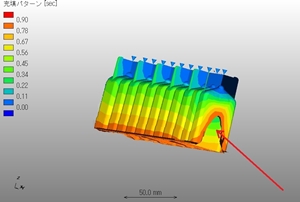

Molding technology realizing high performance by a special grade plastic molding technician

From plastic product prototype development to mass production, a special-grade plastic molding technician will respond consistently. Because the special-grade plastic molding technicians handles not only perform molding but also mold design, ultra-thin, high-precision molding and stable quality molded products are realized.

-

- Molding technique to realize ultra-thin molding and high-precision molding

Mold technology for plastic products that realizes shapes rejected by other companies in the industry

Shinwakogyo has mass-produced many production projects rejected by molding companies in the same industry. With high technology from mold design to manufacturing, we realize the shape, quality and mass production system required for commercialization.

-

- Design and manufacturing technology of mold that realizes shapes rejected by other companies in the industry

Complete manufacturing site specialized for medical device manufacturing and medical products

We have complete equipment and environment for manufacturing medical plastic products, such as injection molding in a class 10,000 clean room with less dust, medical device manufacturing approval and ISO certification.

-

- Complete equipment and environment for manufacturing medical plastic products

Inquiry

Inquire from the inquiry form of this page or ask on the phone

Ask us your requests from the inquiry form below. Detailed information like with drawings makes process smooth.

Proposal

Estimation/design based on drawings, and more, we can propose for improvement

Not only just manufacturing along the requests from you but also we can estimate the design/manufacturing costs by the discussion with customer or estimate with VE proposals based on the drawings from you.

Quotation

Quotation based on customer's requests

We propose quotation based on the inquiry from you.

We consider the business terms and delivery location and so on to make smooth dealing.

Order

Final specification confirmation and ordering

We confirm you the final specification based on the proposed quotation. And then we receive official order from you.

Manufacturing

Manufacturing and delivering with dedicated facilities and well experienced engineers

We will conduct sheet metal processing, welding, painting, assembling of control devices, rudder design, design/manufacturing of control boards, consideration of temperature/noise/IP specifications and acquirement of approvals/qualifications. And then deliver the products to you.