Shinwakogyo Co., Ltd. operating "MedicalPlasticMolding.com" has been asked for advice by engineers, professors, medical doctors etc. regarding "development of new product", "improvement of conventional products", "development of improvement model of foreign products". This page describes all of the services Shinwakogyo has addressed for them. Please have a look them, and then ask us if you have any problem regarding development/improvement of medical plastic products.

Accomplishments of developed products of "MedicalPlasticMolding.com"

Here we introduce some examples of record that Shinwakogyo Co., Ltd. operating "MedicalPlasticMolding.com" was consulted and then achieved as a commercialization of product.

-

- Vessel for gender preselection jellySize: φ25x110

-

- Syringe pistonSize: 23x10x110

-

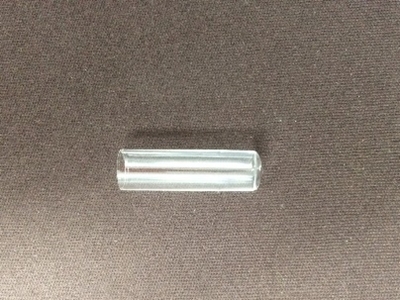

- Thin-wall tube moldingSize: φ5 x 12

-

- Super small ultra thin-wall tubeSize: 29xφ8.4 Wall thickness:0.4

-

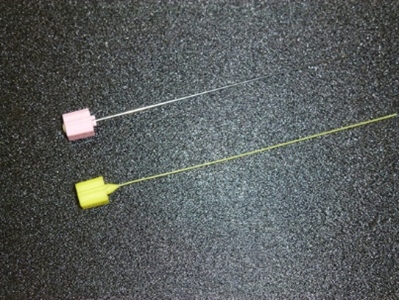

- Anesthesia needleSize: φ8.0 x 125

-

- Thin-wall pipetting tipSize: φ8.0 x 100

-

- Medicine vessel part spoutSize: φ40-50 x 50-60

-

- Antitamper capSize: φ50-90 x 040-80

-

- Super thin-wall tube capSize: φ8.0 x 10

-

- Tip for cord bloodSize: φ19 x 170

-

- Bobbin shape functional part for medicalSize: φ5 x 30

-

- Plug for medical syringeSize: φ50-90 x 040-80

We have medical second-class marketing license for medical devices,

registration certificate of medical device manufacturer and certification of ISO13485

We have not only technique and quality but also Second-class marketing license for medical devices, registration certificate of medical device manufacturer and the qualification of "ISO13485" which can be certain proof on the medical plastic molding manufacturing.

Please consult us with confidence.

Molding know-how by special plastic molding specialist

We have two persons who has certificate of "Special plastic molding specialist" which is most difficult technical certificate in the certificates of national qualifications for plastic molding. We can make proposals from the stage of design to molding with our rich knowledge and experience.

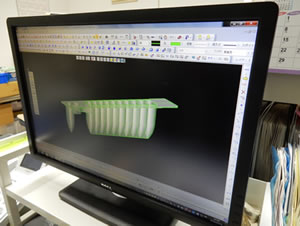

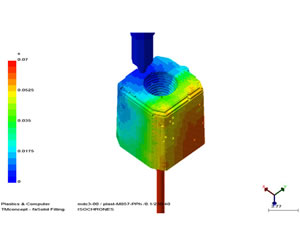

Proposals of product shape with consideration of quality and cost

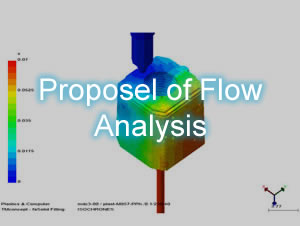

We are constantly develop medical plastic products with customers. To achieve stable production with low cost, we propose optimized product shape by using flow-analysis.

Mold design and manufacturing by analysis with experience and knowledge of medical device development

Not only to molding of medical plastic products but also we can design molds for customer's products. We design and manufacture optimized molds through the steps T0 and T1 with our experiences and 3D flow-analysis.

Plastic molding in the clean room of class 10,000

The molding machines of Shinwakogyo are installed in the clean room of class 10,000 which is much less dusts. Thus, we realize the quality of medical plastic products including packaging process.

Inquiry

Inquire from the inquiry form of this page or ask on the phone

Ask us your requests from the inquiry form below. Detailed information like with drawings makes process smooth.

Proposal

Estimation/design based on drawings, and more, we can propose for improvement

Not only just manufacturing along the requests from you but also we can estimate the design/manufacturing costs by the discussion with customer or estimate with VE proposals based on the drawings from you.

Quotation

Quotation based on customer's requests

We propose quotation based on the inquiry from you.

We consider the business terms and delivery location and so on to make smooth dealing.

Order

Final specification confirmation and ordering

We confirm you the final specification based on the proposed quotation. And then we receive official order from you.

Manufacturing

Manufacturing and delivering with dedicated facilities and well experienced engineers

We will conduct sheet metal processing, welding, painting, assembling of control devices, rudder design, design/manufacturing of control boards, consideration of temperature/noise/IP specifications and acquirement of approvals/qualifications. And then deliver the products to you.